Recuperator

RECUPERATOR

Plate heat exchangers are those that make it possible to transfer heat between two airflows operating at different temperatures

The use of such equipment enables considerable savings to be achieved in the operating costs of air-conditioning plant, and thus the saving of energy that would otherwise be lost

Please find here below the Basic Features for plate heat exchanger

Low costs of installation and operation

Complete separation of flows

Absence of moving parts

Easy adaptability to any use

Products with materials suitable for different environments

Low pressure-drop

High efficiency

Easy to clean and minimal maintenance

Effective action for noise-damping purposes

Application

Air Conditioning and Heating

Swimming pool and Hospital

Industrial ventilation

Air replacement with recovery

Spray booth

Heat recovery from flue gases

Data Center

Application

Air Conditioning and Heating

Swimming pool and Hospital

Industrial ventilation

Air replacement with recovery

Spray booth

|

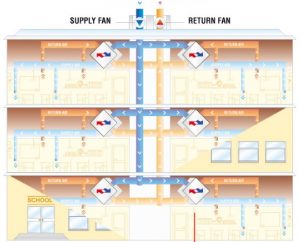

| We can imagine a 20 classrooms school. Every time we open the window for the necessary air refreshing, the room temperature suddenly falls (uneasiness). To reach the comfort temperature again, the boiler has to burn a great quantity of fuel (that means energy costs and pollution). By installing a heat recovery system, the supply air flow receives free heat from the exhaust air flow while entering fresh air in the classroom. In this way, no rapid changes occur in temperature (easiness) and less quantity of energy is necessary to reach the comfort temperature. Then, a heat recovery system has been installed including one of our plate heat exchangers for each classroom(model BX AL 04 N 0400 R 1 AR CD SC, as detailed here).Saving for each classroom: 38 $/monthTotal saving for the school 760 $/month 9120 $/yearPAY-BACK OF THE INVESTMENT: ABOUT 13 MONTHS |